Industrial Mixing. Reinvented.

Cut Hours of Mixing Down to Just Minutes

Mixing shouldn’t take all day. AquaShear gets it done in under an hour. Without waste, sludge, or costly downtime. Backed by over three decades of proven performance, our technology saves you money, time, and headaches.

AquaShear IP Acquired in 2022

Johnson Specialty Tools Founded in 2014

Up To 90%

Faster Mix Time

52%

< 9

99%

Why Switch to AquaShear?

Most mixers waste time and chemicals. Ours cuts mix time by up to 90%, uses less product, requires minimal maintenance, and is applicable to a diverse range of industries.

Ultra-Fast Mixing

Proven Cost Savings

Minimal Maintenance

About 45 minutes per quarter, plus a 15-minute clean/debris removal process if needed.

No Blades. Just Power.

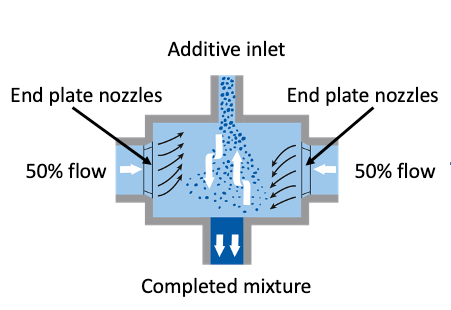

Multiple strong streams of fluid oppose each other inside our chamber. That force creates a fast, even mix without moving parts. It’s clean, quiet, and almost impossible to clog.

Precision Hydraulic Systems

Opposing streams enter the chamber, aligned within a specific degree to generate a powerful vortex. All particles are instantly emulsified without any mechanical shearing, delivering uniform mixing with zero sediment.

- Powerful vortex generation

- Zero moving parts

- Dustless operations

- Uniform particle distribution

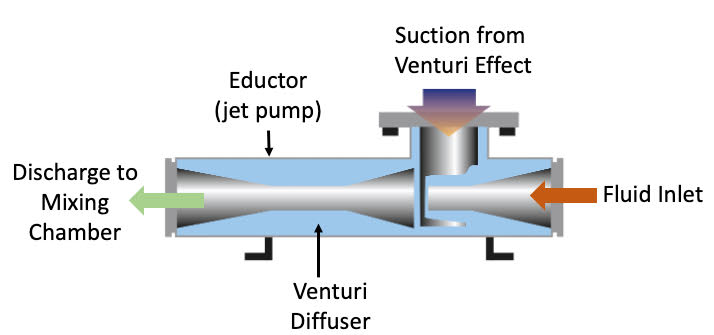

Venturi Effect Technology

Our eductor system uses an elliptical Venturi to create powerful suction and mixing action. The jet nozzle design ensures consistent performance across varying flow rates and pressures.

1 sec

< 4 hrs

Real Numbers You Can Trust

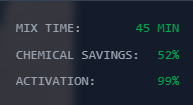

Lab tests hit 99% polymer activation in one second. Field trials cut blend time from six hours to 45 minutes. Data logging to SCADA is available through partnership or additional technology purchase.

99%

45 min

52%

< 9 mo

Engineered for Your Conditions

Standard units are built from carbon steel with polyurethane nozzle disks for grit and wear. For food or pharma, choose 304 stainless steel units with Teflon nozzle disks and food-grade gaskets. For acids or caustics, we use 316 stainless steel with Delrin nozzle disks and Viton gaskets. High-temp polyurethanes handle up to 250°F.

Quick Hook-Up and Minimal Care

< 4 hrs

15 min

- Standard Victaulic or ANSI flanges

- No bearings or seals to fail

- Skid-mounted for easy integration

- SCADA data logging available through partnership or additional technology purchase

- Units can be designed for most flow rates, with chamber sizes from 1" to 14" to match your mixing needs

Material Options

Standard Polyurethane

Tough construction for grit and wear resistance in demanding industrial applications

Stainless Steel Construction

Acids, caustics, and high-temperature applications up to 250°F

One Solution. Many Uses.

Oil & Gas

Petro Chemical

Polymer production, catalyst blending, chemical formulation

Mining

Water Treatment

Food Processing

Pharmaceuticals

Want to See the Savings?

Want the Specs?

Data Sheet

White Paper

Talk to an Expert

Get in Touch

Need pricing? Have questions? We’ll help you get started. Reach out now and see what AquaShear can do for your plant.