Coagulant mixing equipment and chemical dosing units make a crucial difference in water and wastewater treatment, affecting how well impurities leave your water supply. Your water would stay full of unwanted substances without the right coagulants, making it unsafe to drink. The water treatment’s coagulation and flocculation processes remove suspended particles and colloids that gravity alone can’t eliminate. The biggest problem water treatment facilities face is getting the coagulant dose right.

Wrong coagulant doses create too much sediment and sludge that become hard to dispose of. The mixing intensity also substantially affects how well coagulation works. Coagulants destabilize and combine colloidal contaminants into larger flocs that sedimentation and filtration processes can remove. Your water treatment operations need precise mixing systems based on coagulation reaction models to work at their best.

This piece gets into how precision mixing technology boosts coagulant effectiveness and pH control in water treatment systems. You’ll find how advanced mixing solutions can cut your coagulant usage, reduce energy consumption, and lower carbon emissions.

The Science Behind Coagulation and pH Adjustment

Charge neutralization and particle destabilization

Suspended colloidal particles in water carry negative electrical charges. These charges make them push away from each other, which stops them from clumping together naturally. The particles are so tiny that they would rarely settle on their own. We used coagulants to neutralize these negative charges with positive chemicals.

The neutralized particles stop repelling each other and bunch together through van der Waals forces. This creates microflocs that grow into bigger, removable clumps. Metal coagulants like aluminum or iron salts also create insoluble metal hydroxide precipitates. These precipitates catch more particles through a “sweep floc” mechanism, much like snow catches air pollutants.

Why pH must be controlled during coagulation

pH levels play a big role in how well coagulation works. Aluminum sulfate (alum), the most common coagulant, works best between pH 6.0 and 7.0. Iron coagulants such as ferric chloride work well in a wider pH range from 5.0 to 11.0.

pH affects how coagulants break down and form metal hydroxide precipitates that remove particles. Research shows that natural organic matter coagulates best at acidic pH levels between 4.5 and 6.0. Turbidity removal works better at neutral pH levels. Water pH below 2 or above 12 can stop aluminum hydroxide precipitates from forming, which makes coagulation less effective.

How mixing influences these chemical processes

Quick mixing, often called flash mixing, makes a big difference in how well coagulation works. This even distribution helps create larger particles that can be removed more effectively during sedimentation and filtration, which could make particles stable again. Research proves that better rapid-mixing creates larger, stronger flocs that remove more particles and dissolved organic matter.

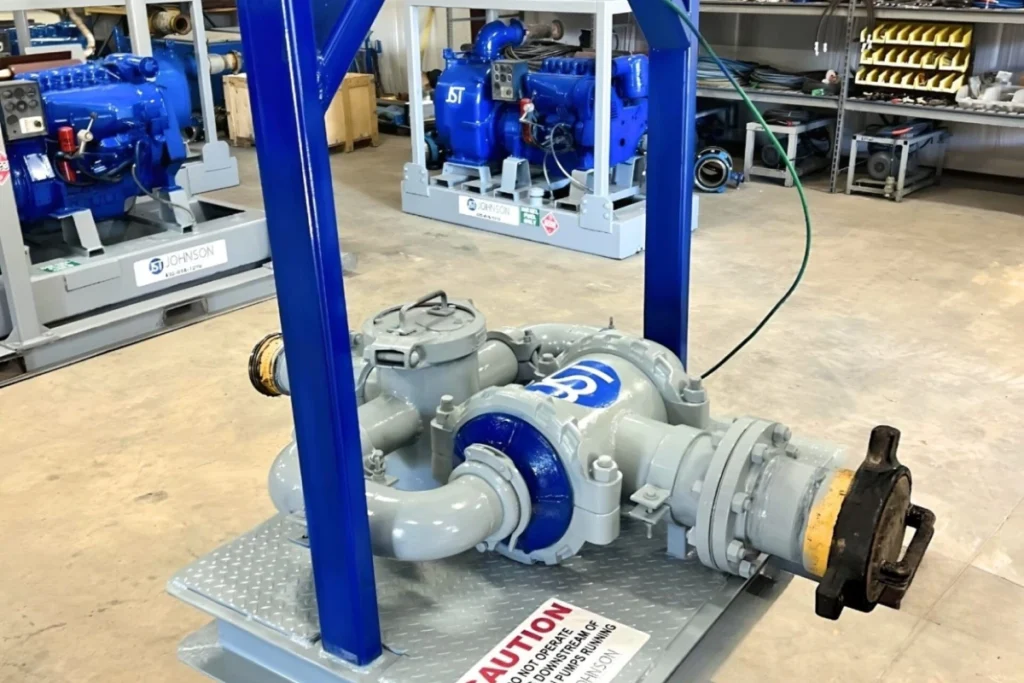

AquaShear’s precision hydraulic system uses opposing fluid streams in a 0.1° nozzle-lined mixing chamber. This creates a strong vortex that blends particles instantly without mechanical shearing or moving parts. Dead zones where chemicals might build up don’t exist in this system. Unlike regular blade mixers, this system spreads chemicals completely in one pass. This cuts chemical use by up to 52% and makes mixing 90% faster.

Problems with Traditional Mixing Systems in Water and Wastewater Treatment

Inconsistent floc formation

In conventional flash mixing systems, impellers often fail to achieve uniform dispersion, leading to dead zones and uneven chemical distribution. Dead zones form where chemicals build up unevenly. This uneven spread results in incomplete coagulation and poor floc development. Water treatment needs properly formed flocs to separate solids from liquids, but traditional systems often produce mixed results.

Flocs rarely go back to their best size and strength once torn apart by uneven mixing. This directly affects how well sedimentation and filtration work downstream. Traditional mixers don’t consistently produce the strong, compact flocs needed to make solid-liquid separation easier.

Overdosing of Coagulants, pH Adjusters, and Chemical Dosing Units

The biggest problem with standard mixing systems is how they tend to overdose chemicals. Studies show that too much coagulant (>20 mg/L) substantially reduces how well the treatment works. This happens because excess coagulant levels cause:

- Charge reversal on suspended particles that leads to re-stabilization instead of clumping

- Extra precipitates that make turbidity worse instead of better

- Weak, fragile flocs that break apart during settling

- “Pin floc” that’s too small and light, so it floats rather than sinks

High maintenance and energy costs

Standard impeller designs make operational expenses higher. These mixers need baffles and other modifications to work better, which makes the system more complex. The systems have more moving parts that wear down, especially during non-stop operation.

These conventional systems use more power too. Research shows better designs can cut energy use by up to 30% compared to old-style mixers. Water utilities already face rising costs, and these inefficiencies create a big financial strain over time.

AquaShear’s precision hydraulic system fixes these problems with its opposing stream design. The system eliminates dead zones and mixes uniformly without mechanical parts. This cuts maintenance time to 45 minutes every three months and reduces chemical use by 52%.

Precision Mixing in Action: What Makes It Effective

Opposing stream design and vortex generation

No blades, no dead zones, no clogging

Instant emulsification of particles

Minimal maintenance and downtime

Why Switch to AquaShear for Water Treatment Coagulants

Up to 90% faster mixing cycles

52% reduction in chemical usage

Adaptable to municipal and industrial systems

Built for high-temp, corrosive, or food-grade fluids

AquaShear’s construction options match your specific requirements:

- Standard units combine carbon steel with polyurethane nozzles for gritty mixtures

- Food/pharmaceutical applications use 304 stainless steel with Teflon components

- Corrosive environments need 316 stainless steel with Delrin nozzles and Viton gaskets

- High-temperature applications require specialized polyurethanes that remain stable at 250°F

Verified performance through CFD modeling

Conclusion

Precision mixing technology transforms water and wastewater treatment by improving coagulant performance, pH control, and efficiency. AquaShear’s hydraulic design eliminates dead zones, disperses chemicals evenly, and reduces chemical usage by up to 52%. With faster mixing cycles and minimal maintenance needs, facilities achieve cleaner water, stronger floc formation, and lower operating costs.

Beyond operational gains, the financial impact is significant, most facilities see ROI within nine months. Whether municipal or industrial, upgrading to precision mixing ensures consistent treatment results, reduced sludge, and more sustainable operations. Request a demo of AquaShear’s coagulant mixing equipment today.