Inline Mixers for Petrochemicals

The fastest way to get a perfect mix in petrochemicals

EFFICIENCY 99% activation

PRECISION 0.1° jet alignment

The Problem with Old Mixing Systems

Most petrochemical mixers slow you down. They leave sludge, waste expensive additives, and break when you need them most. Static mixers create dead zones. Batch mixers take hours. Moving parts fail during production. This means higher costs, wasted chemicals, and lost uptime.

The AquaShear Answer

We built AquaShear to solve these problems. No blades. No clogs. No downtime. Two liquid streams collide in our chamber, creating a strong vortex, a unique process that mixes instantly. That means a complete mixing process for polymers, resins, and chemicals, all in one pass.

- No moving parts means less maintenance and more uptime

- Mixing in one pass, instant and full dispersion

- Engineered design ensures dependable, consistent results

- Trusted worldwide for more than 20 years

How High Shear Mixing Works

0.1° nozzle alignment

proper design that delivers perfect turbulence every time

Instant vortex mixing

consistent results in one run

Advanced flow modeling

proven across viscosities and pressures

Maintenance-free

no moving parts to break down

How High Shear Mixing Works

The design is simple but powerful. Multiple flows meet inside the chamber and create a swirling force. This shear effect mixes particles, liquids, and additives instantly. No sludge. No waste.

0.1° Nozzle Alignment

proper design that delivers perfect turbulence every time

Instant vortex mixing

consistent results in one run

Advanced flow modeling

proven across viscosities and pressures

Maintenance-free

no moving parts to break down

Easy to Use, High Shear Performance

- 99% activation of polymers.

- 45 minutes to complete a mix vs. 6 hours with batch systems

- Up to 52% savings on chemicals and stabilizers

- Only 15 minutes of cleanup every three months

- Installation in less than four hours

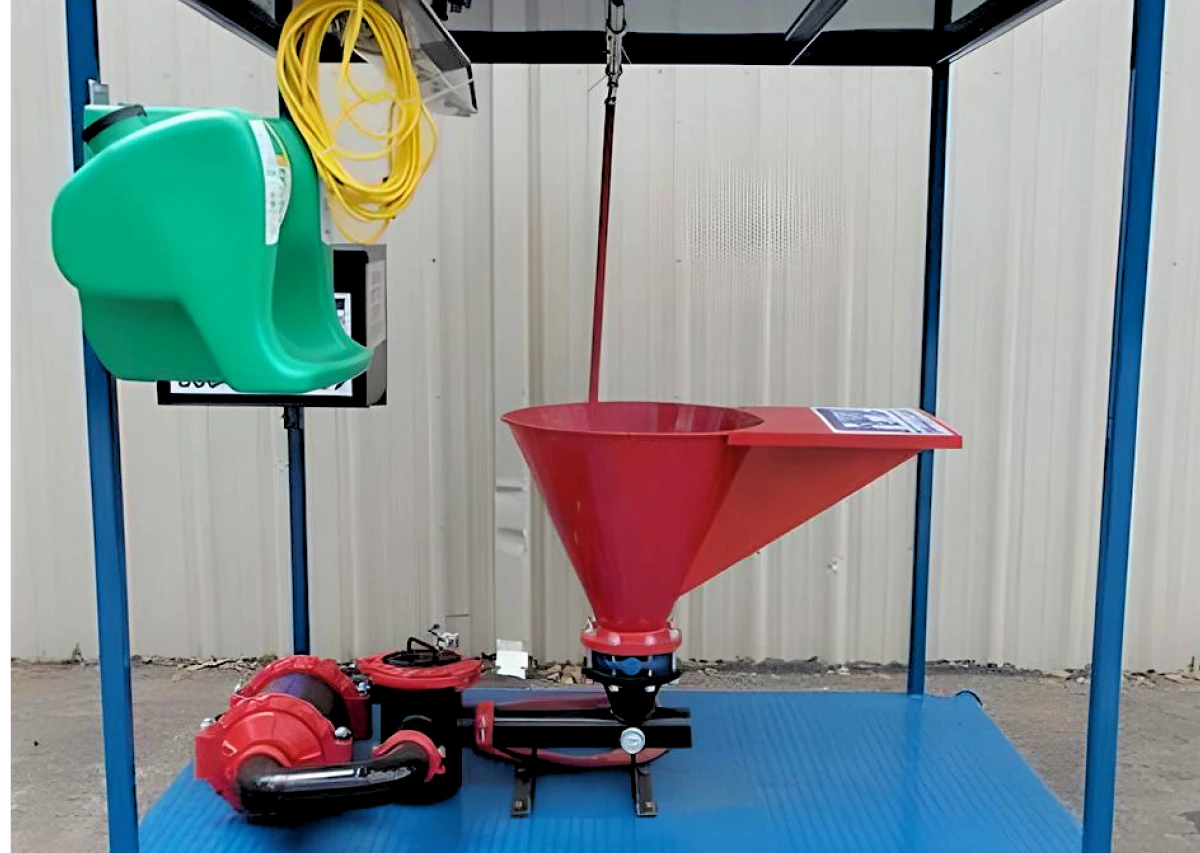

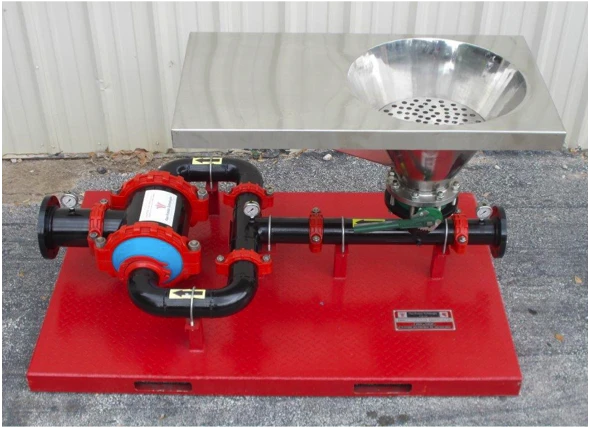

- Flexible integration: inline loop or skid-mount

- Standard connections: ANSI or Victaulic flanges

Petrochemical Inline Mixer Applications

The petrochemical industry runs on speed, uptime, and consistency. AquaShear delivers all three. It handles liquids, gases, and additives without clogs or downtime.

- Refining oil and chemical injection

- Processing plastics and resin

- Additive dispersion in pipelines

- Gas/liquid mixing

- Cooling and temperature control systems

Refining oil and chemical injection

Processing plastics and resin

Additive dispersion in pipelines

Gas/liquid mixing

Cooling and temperature control systems

How We Solve Petrochemical Mixing Challenges

Faster production

cycles cut from hours to under one hour

Lower costs

up to 50% less chemical usage

Reliable uptime

no moving parts to fail

Consistent results

tested and proven for reliable performance

Why You Should Choose AquaShear

When uptime and efficiency matter most, AquaShear delivers. With more than 20 years of proven results in critical industries and developed by the original VP of Operations, it’s engineered for reliability where it counts. Offering ROI in less than nine months, AquaShear removes the gamble from performance and provides results you can trust.

Frequently Asked Questions

What makes AquaShear different from other inline mixers for petrochemicals?

Most inline mixers use blades or tanks. That means slow cycles, uneven mixes, and wasted additives. AquaShear uses a vortex with no moving parts. It blends liquids, resins, and chemicals in one pass with no sludge or dead zones.

Can AquaShear replace static mixers?

Yes. Static mixers often create pressure drop and dead zones. AquaShear gives complete mixing across the entire chamber with no waste. You get faster dispersion, higher efficiency, and lower chemical use.

Stainless Steel or Carbon Steel: What Materials Is the Mixer Made From?

We build AquaShear in stainless steel or carbon steel, depending on your needs. Both meet the high requirements of petrochemical plants. This makes the mixer the best solution in harsh conditions with high temperature, pressure, and viscosity.

How does it handle high-viscosity fluids or heavy-duty applications?

The system was designed for industrial applications. Whether you run light chemical injectants or thick resins, AquaShear delivers complete dispersion. No clogs. No grinding parts. No downtime.

Do I need expensive upgrades to install it?

No. AquaShear connects to standard pipe systems. Victaulic or ANSI flanges make installation fast. Most plants install in less than four hours with no major changes to the line.

How often do I need to clean or service the mixer?

Almost never. With no moving parts, AquaShear only needs a quick 15-minute cleanup every three months. Compare that to batch tanks and static mixers that require frequent servicing.

How fast will I see a return on investment?

Most petrochemical companies see ROI in less than nine months. Lower chemical use, shorter cycles, and higher uptime make the savings clear.

Is it suitable for continuous operation?

Yes. AquaShear was built for nonstop petrochemical production. It runs for long cycles without maintenance or cleaning breaks.

How does it compare to batch mixers?

Batch mixers take hours and waste energy. AquaShear cuts cycles from six hours to 45 minutes. It delivers instant, complete dispersion without the tanks, blades, or downtime.

Is it sustainable?

Yes. AquaShear cuts chemical use by up to 50%. Less chemical waste means lower costs and a smaller environmental impact.

Can one system adapt if my products change in the future?

Yes. AquaShear handles a wide range of fluids, additives, and viscosities. One unit can be used across multiple petrochemical processes without replacement.

What industries outside petrochemicals use AquaShear?

While designed for petrochemical plants, AquaShear is also trusted in water treatment, food, plastics, and paper industries. The same mixing technology adapts to many industrial applications.