Your drilling fluid can last two to three times longer with optimized drilling mud mixing equipment, which plays a critical role in the drilling process. The right mud system size will improve drilling performance, cut downtime, enhance reliability, and lower the costs of solids disposal.

A solids control system needs to process at least 100% to 125% of the circulating mud to work well. Drilling experts suggest that your drilling mud mixer’s processing rate should be 1.5 to 2 times higher than your drilling rig’s rate for the best balance.

On top of that, a detailed solids control program cuts fluid dilution rates, needs fewer additives, and makes drilling fluid properties better, including optimal oil water ratio drilling mud systems.

Make Sure Your Drilling Mud Mixing Equipment is Properly Balanced

Why balance matters in solids control

The main goal of a balanced mud system is to remove unwanted solids effectively and maintain essential fluid properties. Your rig will perform substantially better with minimal downtime when the system operates in perfect harmony. More effective solids removal on the first pass can extend your drilling fluid lifespan by two to three times. This creates substantial savings throughout the project.

Balanced systems offer measurable benefits beyond cleaner fluid. Equipment lasts longer because of reduced wear and tear. You’ll also lower operational expenses through decreased waste generation and fluid replacement needs. Systems without proper balance create many operational challenges, from stuck pipe to reduced drilling rates, increased torque, and formation damage.

Sizing your system to match rig capacity

You should select processing capacity 1.5 to 2 times greater than your drilling rig’s requirements. This will give a solids control equipment setup that handles peak drilling conditions without becoming overtaxed. The ideal cleaning volume should be 20 to 50% more than your continuous rated pumping needs when sizing a mud system for a specific job.

Ground conditions heavily influence where you land on this spectrum. Removing sugar sand needs cleaning capacity closer to the 50% mark. Rock removal lets you operate closer to 20%. Each 5-inch cone processes approximately 80 gpm in hydrocyclone configurations, while 10-inch cones handle up to 500 gpm each.

Avoiding overloads and underperformance

Undersized systems trigger a cascade of problems throughout your drilling operation. Poor-quality drilling fluid returns to the borehole when solids control equipment can’t match drilling rate. This causes complications and operational delays. Downstream equipment like hydrocyclones and centrifuges becomes overloaded beyond intended capacity.

Your system should be hydraulically balanced with the ability to make both scalp cuts and fine cuts to prevent these issues. The mud system should process at least 100% to 125% of the circulating mud rate. So this stops drilling from outpacing your capacity to maintain low gravity solids at safe levels. Such scenarios can lead to increased swab and surge pressure, wellbore pressure containment issues, and even complete well failure.

Note that manufacturer ratings often assume ideal conditions rarely found in the field. Slightly oversizing your system gives valuable operational flexibility without compromising performance.

Maintain Equipment for Long-Term Efficiency

Daily shaker screen inspections and cleaning

You should inspect shaker screens daily to find tears, holes, or improper seating. A small hole can allow solids to bypass the screen and damage downstream components. The screens need cleaning with a water hose or pressure washer after each drilling shift. Never use wire brushes because they damage the mesh. The screen life lasts longer when you spray water at an angle, not directly on the screen, with maximum 1,000 psi pressure.

The deck rubbers need checking for wear or damage. Replace all four rubbers in a section if any show signs of wear. Properly seated screens are crucial. You can test this by stepping on the screen from the discharge end. The screen isn’t secure if additional material discharges.

Hydrocyclone pressure and cone wear checks

Hydrocyclones require adequate pressure, minimum 30 psi, at the time of operation. Each cone needs testing by feeling for suction at the bottom while running. Internal inspection of new cyclones should happen at least every two months until you determine the actual wear rate.

Worn liners need replacement when they are nowhere near one-third thickness. Note that wear increases toward the cyclone’s bottom where velocities peak.

Centrifugal pump alignment and seal care

The pump and motor shafts must be arranged correctly to prevent vibration and seal failure. The baseplate should be level with tight mounting bolts before alignment. A laser alignment tool or dial indicator helps measure and adjust both angular and parallel alignment.

Fluid leaks often signal seal failure and need immediate attention. Shaft sleeve issues cause most failures, about 90%, rather than mechanical seal problems.

Winterizing and anti-freeze tips for idle systems

The system needs complete drainage after use via the low-point drain during cold weather. Antifreeze should go into the pump since removing all fluid is challenging. Some contractors keep continuous circulation or add heaters in tarp-covered areas during extended idle periods in freezing conditions.

A small hand pump helps circulate 50-50 radiator fluid through the manifold to winterize hydrocyclones properly.

Proactive maintenance to reduce downtime

Your specific operating conditions should determine the maintenance schedule. Specific personnel need training and designation to oversee equipment maintenance. An adequate inventory of recommended spare parts and screens complements regular inspections.

WD-40 or PB Blaster applied weekly prevents Victaulic clamps and ball valves from freezing in position. The machine needs a good wash when relocating to remove all mud and debris, with clean water flushed through the system.

Choose the Right Equipment for Your Operation

Double-deck shale shakers for better separation

API 13C shaker screens and their importance

Hydrocyclone configuration for optimal flow

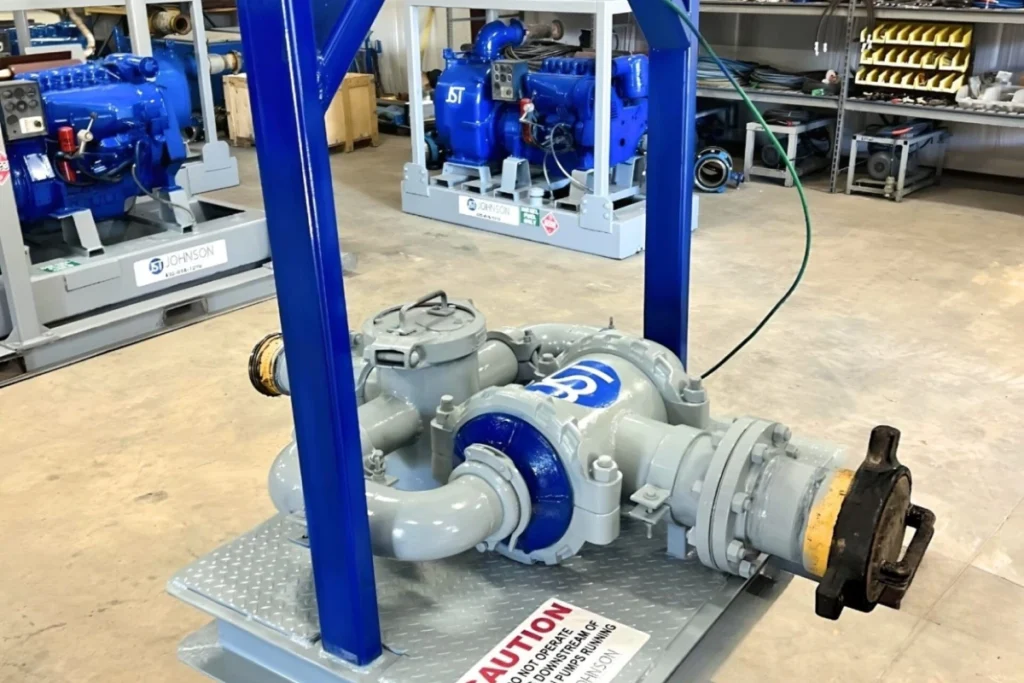

Abrasion-resistant centrifugal pumps

Integrating oil water ratio drilling mud systems

Use an Advanced Mixing System Like AquaShear

How AquaShear reduces mix time by 90%

Eliminating sludge and sediment with vortex mixing

Field-tested 52% chemical savings

Minimal maintenance and no moving parts

Precision hydraulic systems for uniform mixing

Applications across drilling and industrial sectors

Conclusion

A properly optimized mud system strengthens the entire drilling process by extending fluid life, minimizing downtime, and cutting disposal costs. The right balance of processing capacity, regular maintenance, and reliable equipment ensures steady performance even under peak drilling conditions.

By choosing advanced tools like double-deck shakers, API 13C screens, and modern mixing systems such as AquaShear, you can streamline solids control while reducing chemical use and improving reliability. The result is fewer delays, longer equipment life, and more profitable drilling operations.

Ready to upgrade your mud mixing system? Contact us today to improve reliability and maximize drilling efficiency.