Your chemical mixing equipment might be costing you more than you realize. Outdated systems slow production, waste energy, and increase safety risks. Holding on to outdated equipment leads to frequent repairs, higher energy bills, and reduced efficiency. Frequent repairs, inconsistent output, and higher energy bills hurt efficiency and profits. Old mixers also struggle with today’s formulations, creating production bottlenecks and quality issues. At some point, repairs stop making financial sense and an upgrade becomes the smarter move.

Here are five clear signs it’s time to replace your chemical mixing equipment and why modern systems like AquaShear can transform your operations.

1. Declining Performance: When to Consider a Chemical Mixing System Upgrade

When your mixer was new, it produced consistent results with minimal effort. But over time, signs of decline creep in.

- Slower batch times: Cycles that once took 30 minutes now stretch past an hour. Operators extend mixing times, tweak settings, or reduce batch sizes just to maintain quality. These “workarounds” inflate labor and energy costs.

- Worn components: Impeller blades develop pitting, seals begin leaking, shafts crack, and bearings vibrate. Each creates inefficiencies and safety concerns.

- Product inconsistencies: Uneven viscosity, clumping, settling, and poor additive dispersion result in higher rejects, wasted raw materials, and customer complaints.

AquaShear’s bladeless hydraulic design eliminates these weak points. No moving parts means no wear, and its precision nozzles (aligned within 0.1°) generate a vortex that delivers uniform, one-pass mixing without dead zones. Unlike traditional blade mixers, AquaShear simultaneously injects chemicals into the chamber for faster, more uniform results.

2. Mounting Repair Costs and Downtime

Keeping old mixers running quickly turns into a money pit.

- Frequent breakdowns: Constant stoppages disrupt production, create contamination risks, and force rechecks of quality.

- Rising costs: Spare parts for older models become scarce and expensive. Service techs spend longer diagnosing issues, raising labor charges.

- Lost trust: Each late delivery chips away at customer confidence, and overtime or expedited shipping adds to your costs.

Once yearly repair bills, lost production, and higher energy use outweigh the cost of new equipment, an upgrade becomes unavoidable. Modern systems not only cut downtime but also integrate materials suited for your needs, from carbon steel for general use to 316 stainless for caustics. Modern designs improve workplace safety by reducing operator exposure during chemical transfer and mixing.

3. Complete System Failure

Sometimes the decision is forced. Catastrophic breakdowns like shaft failure, bearing collapse, or severe corrosion can halt production entirely.

- Loud abnormal noises or excessive vibration

- Safety hazards from leaks or compromised seals

- Prohibitive repair costs due to obsolete or overpriced parts

Most mixers hit this “failure threshold” around the 5–6 year overhaul mark. At this point, repairs often cost more than new equipment.

AquaShear avoids these pitfalls altogether. With no impellers, bearings, or seals, there are no traditional failure points. Lab tests show 99% polymer activation in one second, while field trials cut blend times from six hours to just 45 minutes.

4. Production Bottlenecks

Even if your equipment still runs, it might be holding back your growth. Traditional mixers can’t keep pace with modern production demands:

- Slow cycles: Hours-long blend times restrict throughput and force costly overtime.

- Manual oversight: Operators spend time monitoring and tweaking settings instead of focusing on higher-value tasks.

- Inefficiency: Traditional systems waste energy and require excess chemicals to achieve target quality.

Advanced mixers with automated controls solve these issues. AquaShear, for instance, enables faster, more consistent batches, integrates easily with existing systems, and reduces chemical usage by up to 52%. Automated controls also help with optimizing loading efficiency, decreasing sprayer loading time, cutting downtime, and ensuring precise chemical usage. Many operations see full ROI in under nine months.

5. Inability to Handle New Formulations and the Value of Modular Design

Modern formulations, whether high-viscosity resins, abrasive slurries, or specialty chemicals, demand more from your equipment. Conventional mixers often can’t:

- Properly disperse thick or abrasive materials

- Maintain precise temperature or dosage controls

- Adapt to varied batch sizes and regulatory demands

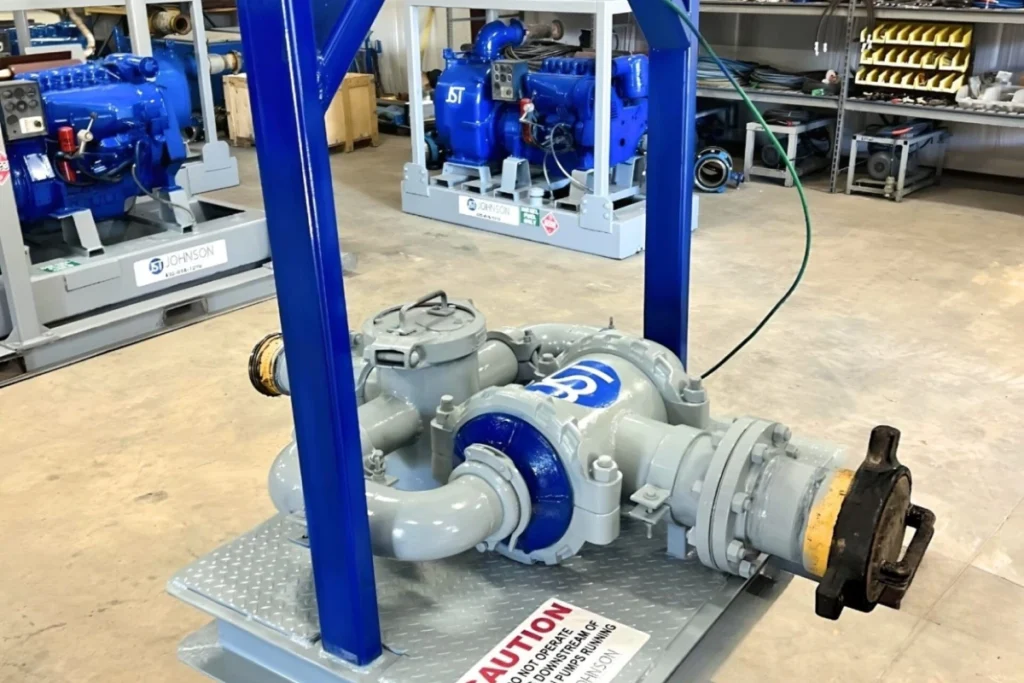

Upgrading provides the flexibility you need for today’s product lines. AquaShear systems come in multiple configurations to handle food, pharmaceutical, and harsh chemical environments. Their modular skid-mounted design installs quickly, integrates with pipe loops, and can be adapted as your production needs evolve.

Why AquaShear?

Ultra-Fast Mixing

Cost Savings

Minimal Maintenance

Material Options

Conclusion

Delaying an upgrade only compounds your costs, slower cycles, higher energy bills, product inconsistencies, and rising repair expenses. The signs are clear:

- Your mixer no longer performs reliably

- Repair costs outweigh replacement

- Complete failure halts production

- Outdated technology creates bottlenecks

- New formulations demand more power and flexibility