Deep Dive into AquaShear Technology

Discover the precision, power, and reliability behind every mix

EFFICIENCY 99% activation

PRECISION 0.1° jet alignment

Precision Hydraulic Systems

How Alignment Creates Perfect Mixing

Opposing streams enter the mixing chamber, creating a powerful vortex that instantly tears particles apart. No blades, no dead zones, no sludge. No mechanical compromise to your additives.

0.1° Nozzle Alignment

Precision-machined nozzles create uniform turbulence across the entire mixing chamber for consistent particle distribution.

Instant, Single-Pass Dispersion

No moving parts means no wear, no maintenance, and no risk of mechanical failure during critical operations.

CFD-Verified Flow

Computational fluid dynamics modeling ensures predictable performance across varying flow rates and pressures.

Materials & Customization

Built for Your Fluid and Conditions

Choose the right build for your needs. Our standard units are constructed from carbon steel with polyurethane nozzle disks for grit and wear. For food and pharma, we build in 304 stainless steel with Teflon nozzle disks and food-grade gaskets. For acids and caustics, we use 316 stainless steel with Delrin nozzle disks and Viton gaskets. High-temp polyurethanes handle fluids up to 250°F.

| Application | Material | Key Benefit |

|---|---|---|

| Standard | Carbon steel with polyurethane nozzles | Long wear life in gritty mixes |

| Food / Pharma | 304 stainless steel with Teflon nozzle disks & gaskets | Meets FDA and USP Class VI |

| Acid / Caustic | 316 stainless steel with Delrin nozzle disks & Viton gaskets | Corrosion resistance |

| High Temp | High-temp polyurethane | Stable at 250°F and above |

Performance & Reliability

Proven Performance and Uptime

99%

45 min

52%

45 min

Quarterly maintenance, plus 15 min cleanup if needed

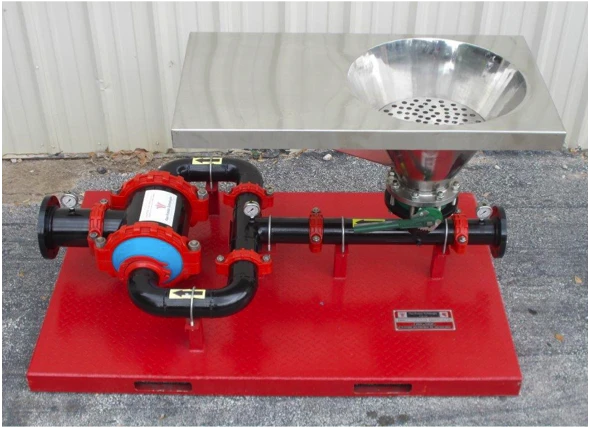

Integration & Installation Guide

Easy Integration into Your System

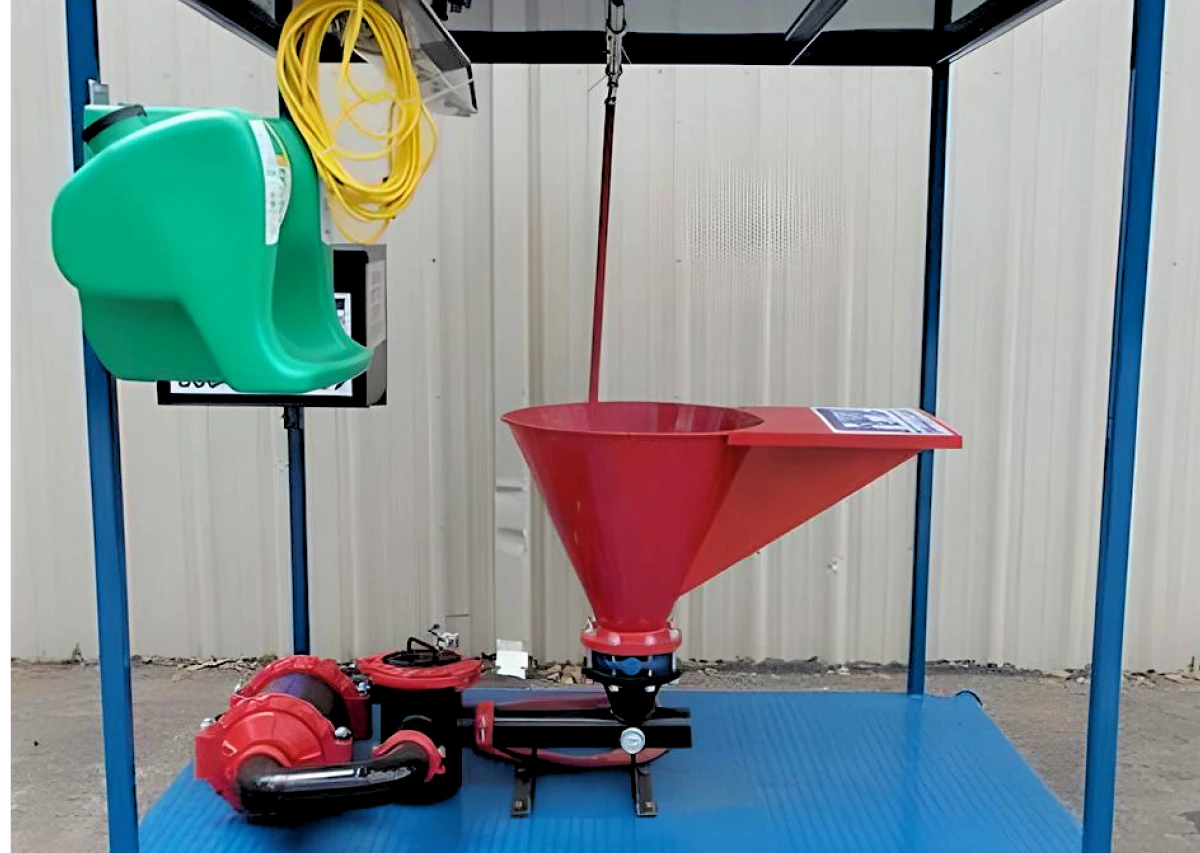

Skid-Mount Setup

- ISO/API footprint

- Forklift pockets

- <4 hr install

Inline Loop

- Victaulic or ANSI flanges

- Bypass valve options

- Standard pipe connections

Controls & Connectivity

- PLC recipe library

- SCADA integration available through partnership or additional technology purchase

- Remote monitoring options

Real Installation Examples