A farm’s profitability takes a hit when slurry mixing systems don’t work at their best. The hidden costs can substantially affect your bottom line. You need accurate evaluation of operational expenses to measure true profitability. Your quality records and proper identification of common cost areas will help reveal these hidden expenses.

The way you mix slurry, liquid manure, or manage your manure pit affects your current costs and your farm’s long-term sustainability. Poor slurry management’s financial effects go far beyond equipment costs. It wastes labor hours, burns extra fuel, and wears out equipment faster. Your fields suffer from uneven nutrient spread that can reduce crop yields and harm soil health. Studies show mixed livestock farms boosted their nitrogen balance by 5% through better practices and cut their greenhouse warming potential by 1–2% through more efficient feed use.

The Cost of Inefficient Farm Slurry Mixing Systems

Labor Hours Lost to Inefficient Mixing on Pig Farms

Fuel Waste from Repeated Mixing Cycles

The difference in energy use between efficient and inefficient mixing is huge. Intermittent mixing (15 min/h) can boost the energy recovery ratio from 31% to 45% compared to continuous mixing.

This impacts your fuel costs. Continuous or repeated mixing cycles burn extra fuel without better results. Proper intermittent mixing boosts methane production and shortens the lag phase better than unmixing and continuous mixing approaches.

Increased Wear and Tear on Slurry Mixers and Other Equipment

Maybe the biggest hidden cost comes from your equipment’s early deterioration. Running equipment continuously under stress wears down your farm’s slurry mixing system, slurry tanks, and storage tanks much faster. Poor maintenance of components like gearboxes, chains, and belts can cause permanent damage.

Equipment failure creates a chain of expenses

- Replacement costs: When equipment stops working properly

- Repair downtime: You have to halt operations while waiting for parts or service

- Emergency service fees: Higher than planned maintenance costs

Heavy loads, constant vibrations, and non-stop use lead to fatigue failure in critical components like frames, axles, and hydraulic cylinders. Small issues turn into major failures without regular inspections and maintenance. This leads to expensive repairs and safety risks.

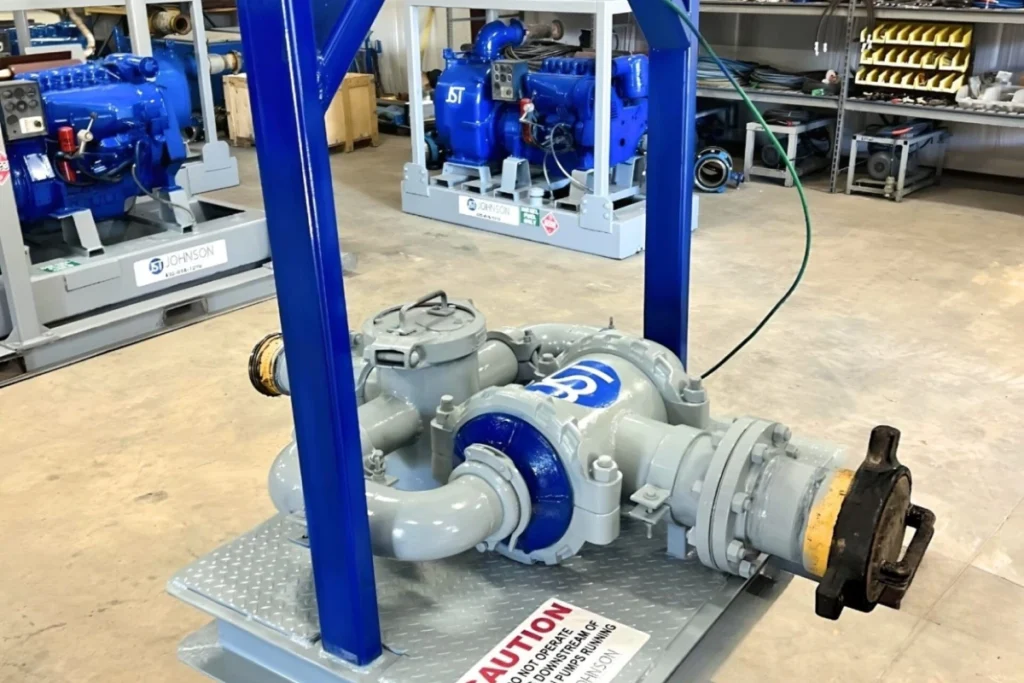

The AquaShear system fixes these problems with precision-machined nozzles that create even turbulence throughout mixing. It has no moving parts, which eliminates common wear points and cuts down maintenance needs and labor costs.

How Poor Mixing Affects Fertilizer and Slurry Application

Uneven Nutrient Distribution in Fields

Nutrient stratification happens when fertilizer components don’t mix evenly in soil layers. Poorly mixed slurry or liquid manure often develops crust forming at the top or floating layers inside slurry pits and tanks. This creates bands with high nutrient concentrations instead of a uniform blend.

This is especially true for phosphorus and potassium that stay put in the soil. Fertilizer mixtures that don’t work well together physically will separate into different layers or solids that settle too quickly. This leads to uneven nutrient ratios when you apply them.

The problem of uneven fertilizer distribution exists in fields of all sizes, even with the best equipment. Your fertilization strategy can fall apart because of this unpredictable distribution, no matter how well you plan it.

Over-Application and Runoff Risks from Slurry Pit and Manure Pit Waste

Slurry that isn’t mixed well leaves nutrients that can easily wash away, especially when it rains. Studies show phosphorus levels stay high in runoff for up to 18 days after you apply slurry or liquid manure. This creates an ongoing threat to the environment. Rain easily carries slurry contaminants from farmland to nearby water bodies. This ends up making water quality worse and causing eutrophication.

These problems get worse when nutrients pile up in slurry pits or fields, which often happens on dairy farms where all but one of these grasslands have too much soil test P values. Your investment literally washes away every time it rains.

Reduced Crop Yield and Soil Health from Poor Liquid Manure Management

Field studies show how uneven fertilizer spreading directly hurts crop performance. Grain yields suffer from distribution problems, with field-scale yields dropping by up to 877 kg DM/ha when fertilizer isn’t spread evenly. Poorly mixed applications can also cause permanent damage to clay minerals and break down soil structure.

The AquaShear system tackles these issues with precision-machined nozzles that create uniform turbulence throughout the mixing chamber. Its 0.1° nozzle alignment will give a consistent particle spread in your slurry or liquid manure, so your crops get nutrients evenly. The system gets complete dispersion in a single pass without moving parts. This eliminates dead zones and sludge buildup that cause uneven application, which protects your yields and keeps your soil healthy.

Operational inefficiencies and their financial impact

Underutilized mixer capacity

Higher maintenance and repair costs

Downtime and delays in feeding schedules

Effect on feed consistency and animal health

Mix-ups in your feed directly affect how well your animals perform, with some ingredients getting mixed too much and others not enough. These mixing problems had a direct link to milk production in dairy farms.

AquaShear’s precision-machined nozzles create even turbulence throughout the mixing chamber. The 0.1° nozzle alignment ensures all particles spread evenly. The system has no moving parts to wear out or fix, which means less maintenance and downtime.

Why AquaShear is a cost-effective solution

Low maintenance and high durability

Efficient slurry mixing with less energy

Improved consistency in farm slurry application

Reduced labor and fuel requirements

Conclusion

Poor slurry mixing quietly drains farm profits. Labor hours are wasted on problem equipment, fuel is burned on repeated mixing cycles, and machinery wears down faster than it should. Even worse, nutrients applied unevenly from slurry pits, manure pits, or tanks reduce crop yields and increase runoff risks that threaten soil and water health. These hidden costs grow season after season, making inefficient systems more expensive than they first appear.

AquaShear offers a smarter alternative. Its no-moving-parts design cuts mixing time from six hours to 45 minutes and reduces maintenance to just minutes each quarter. Precision-machined nozzles create uniform turbulence that eliminates dead zones, giving crops an even nutrient spread while lowering chemical costs. Many farms see a return on investment in less than nine months.

By switching to efficient mixing technology, you’ll protect your equipment, improve soil health, and strengthen long-term farm productivity. Request a demo of AquaShear today.