Order an AquaShear Inline Mixer

The smallest model starts at $1,500, with final pricing based on size, materials, and system requirements. Contact us for details.

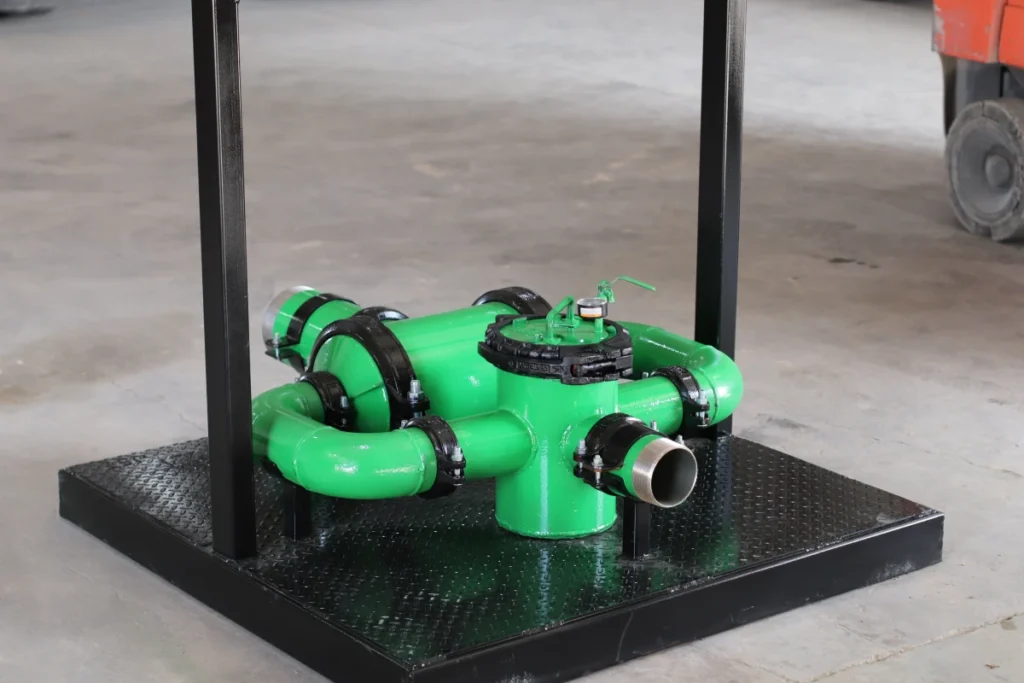

Standard Inline Mixer

- Gritty mixes

- General industrial use

- Water, drilling mud, slurries

Food & Pharma Inline Mixer

- Food processing

- Pharma

- Clean manufacturing

Acid / Caustic Inline Mixer

- Chemical plants

- Corrosive fluids

- Harsh environments

Shipping Information

AquaShear mixers are built to order. Lead times range from 6 to 12 weeks based on size and application. Units ship through freight carriers, and customers may request a preferred carrier if needed. Shipping costs are calculated based on the final configuration and destination and will be included in your quote.

Payment Options

AquaShear mixers can be purchased through purchase order or wire transfer. Payment information will be included with your quote.

Returns and Warranty

AquaShear mixers are custom built for each customer’s needs, so returns cannot be accepted. Each unit includes a warranty on construction. Normal wear or misuse is not covered under this warranty.

Frequently Asked Questions

How does the AquaShear Inline Mixer work?

What industries use AquaShear mixers?

AquaShear inline mixers are used in the following industries.